Cost Breakdown of Cosmetic Packaging

This page breaks down the real cost differences through five key factors: materials, craftsmanship, structure, shipping, and MOQ.

The Same Product Can Cost $0.10 or $10

These two bottles may look identical, but differences in materials, manufacturing processes, and structural design can make one cost ten times more than the other

Cheap

PET Material + Injection Blow Molding

Cheap

Acrylic Material + Injection Blow Molding + Metalizing + Spray Coating

Cheap

Glass Material + Mould Pressing

Expensive

Glass Material + Mould Pressing + Full-Body Spray Coating

Cheap

PET Material + Injection Blow Molding

Expensive

PET Material + Injection Blow Molding + Spray Coating + Silk Printing

Let’s talk about your packaging needs

Please briefly tell us the type of product you’re selling (e.g. serum, cream, mist), the capacity, bottle style, and material. We’ll recommend a suitable packaging solution based on your budget.

🧾 The 10 Key Factors in Packaging Structure That Affect Cost

| Section Title | Common Customer Question | Cost Impact & Reasons | Cost-Saving Suggestions |

|---|---|---|---|

| 1. Material Type Matters | “These two bottles look almost identical — why is one double the price?” |  Different resins = different costs. PETG, acrylic, and PET deliver higher gloss and rigidity, but are more expensive. PP/PE are cost-efficient and flexible, widely used for large-volume or mid-tier lines, and can also achieve premium looks with the right finishing. Visual similarity ≠ equal cost. Different resins = different costs. PETG, acrylic, and PET deliver higher gloss and rigidity, but are more expensive. PP/PE are cost-efficient and flexible, widely used for large-volume or mid-tier lines, and can also achieve premium looks with the right finishing. Visual similarity ≠ equal cost. | Use PP/PE to control costs; pair with matte or glossy coating to simulate a high-end look. |

| 2. Material Quality & Density | “Both are PET bottles — why is yours heavier and more expensive?” |  Price is influenced by virgin vs recycled resin, gram weight, wall thickness, and consistency. Price is influenced by virgin vs recycled resin, gram weight, wall thickness, and consistency.  Faster production lowers cost but reduces durability and gloss. Faster production lowers cost but reduces durability and gloss. | Choose a weight and thickness that align with your brand tier. |

| 3. Surface Finishing & Decoration | “This bottle looks so premium — is it plated or just sprayed?” |  Metallic effects come at different price points: Electroplating > Spray coating > Silk printing. Gradient and pearl finishes raise both MOQ and cost. Metallic effects come at different price points: Electroplating > Spray coating > Silk printing. Gradient and pearl finishes raise both MOQ and cost. | Use silver/gold spray with clear topcoat to mimic plating. Hot stamping adds detail without major cost increases. |

| 4. Structure Complexity | “Why does a double-wall bottle cost 30–60% more than a single wall?” |  Double-walls require more resin, tighter precision, and bonding. Double-walls require more resin, tighter precision, and bonding.  Integrated pump designs = higher mold cost + stricter QC. A premium feel often equals complex engineering. Integrated pump designs = higher mold cost + stricter QC. A premium feel often equals complex engineering. | Consider single-layer bottles with advanced coatings for a similar premium look. |

| 5. Mold Setup & Output | “We just tweaked the neck shape — why do we need a whole new mold?” |  Public molds are fixed; even minor geometry changes require new tooling. Cavity count (2→4→8→16) impacts both output speed and upfront investment. Public molds are fixed; even minor geometry changes require new tooling. Cavity count (2→4→8→16) impacts both output speed and upfront investment. | Leverage 100+ available public molds, or explore shared mold development to lower costs. |

| 6. Production Equipment | “Why does your printing look sharper?” |  Modern servo machines = faster, more precise, and support multi-color printing in one pass. Older or manual machines risk misalignment or blur. Modern servo machines = faster, more precise, and support multi-color printing in one pass. Older or manual machines risk misalignment or blur. | Partner with suppliers using advanced equipment for consistent and sharp results. |

| 7. Component Assembly Management | “It’s just a pump, right? Why is the labor so high?” |  Complex structures like refill systems, airless pumps, or multi-layer bottles require manual assembly of gaskets, springs, collars, and alignment. Complex structures like refill systems, airless pumps, or multi-layer bottles require manual assembly of gaskets, springs, collars, and alignment.  High-tolerance fit = slower assembly. High-tolerance fit = slower assembly.  Automation is only possible for standard designs. Automation is only possible for standard designs. | Simplify internal structures or choose automation-friendly designs. For complex pumps, consider split shipping (pump and bottle separately). |

| 8. Quality Control Standards | “Why is your defect rate lower than others using the same mold?” |  Strong QC means multiple checkpoints: incoming material, in-line process, and final product. Many skip these to cut cost. Strong QC means multiple checkpoints: incoming material, in-line process, and final product. Many skip these to cut cost.  Additional fatigue and pressure tests = better assurance. Additional fatigue and pressure tests = better assurance. |  Apply sampling checks during production to control defect rates without extra burden. Apply sampling checks during production to control defect rates without extra burden. |

| 9. Eco-Friendly Packaging Systems | “Isn’t refillable packaging supposed to save money?” |  Refillable systems mean more parts: inner pods, seals, locking mechanisms. Adds 25–50% to cost, especially if custom-fit. Refillable systems mean more parts: inner pods, seals, locking mechanisms. Adds 25–50% to cost, especially if custom-fit. | Use hybrid models: keep the outer shell, replace only the pod. Or switch to PCR, bamboo, or glass in classic formats. |

| 10. Packing Method & Shipping Readiness | “Shipping cost doubled just because we added pump assembly?” |  Assembled parts increase height, take more space, and scratch more easily. Assembled parts increase height, take more space, and scratch more easily.  Bagging or boxing adds labor, packaging, and freight cost (+10–40%). Bagging or boxing adds labor, packaging, and freight cost (+10–40%). | Ship components separately where possible. Simulate carton layout and shipping volume in advance to avoid waste. |

The choice of material can make a big difference in cost

They may both look like clear bottles, but why is PET almost half the price of PETG? Because each material differs significantly in terms of cost, texture, durability, and product compatibility.

| Material | Relative Cost (vs. PET) | Visual & Texture | Key Features | Recommended Applications |

|---|---|---|---|---|

| PET |  Base cost Base cost | Clear, lightweight | Low cost, versatile, impact-resistant, safe for shipping | Toners, sprays, mass e-commerce products |

| PP |  +10%~20% +10%~20% | Opaque, matte | Soft, good chemical resistance, suitable for sensitive formulas | Cream jars, shampoos, baby skincare |

| AS |  +15%~25% +15%~25% | Glossy, clear but brittle | Attractive look but low impact resistance, often used for displays | Gift box outers, shell components |

| PETG |  +30%~50% +30%~50% | Thick, crystal-clear, glass-like | Premium feel, ideal for mid/high-end visual packaging | Serums, anti-aging lines, PET upgrade option |

| Acrylic |  +40%~60% +40%~60% | Heavy, glossy, glass-like | High hardness, easily scratched, visually premium | Luxury cream jars, showcase packaging |

| PE |  +10%~20% +10%~20% | Semi-transparent/matte | Soft, squeezable, durable — ideal for tubes | Sunscreen, BB cream, travel-size products |

| Glass |  +60%~100% +60%~100% | Most premium, heavy & solid | Excellent for oxidation-prone formulas, fragile, high shipping cost | Serums, ampoules, high-end functional skincare |

| Aluminum |  +30%~60% +30%~60% | Metallic, matte or glossy | Lightweight, recyclable, strong eco image | Sunscreen, perfume, eco-friendly premium lines |

| Bamboo / Pulp Mold |  +40%~70% +40%~70% | Natural texture, raw feel | Sustainable, earthy style, moisture-sensitive | Gift sets, refill caps, organic/natural brands |

PET

Cost Efficiency: Low cost, ideal for sampling, small runs, or mass production.

Durability: Lightweight, shatter-resistant, suitable for e-commerce.

Decoration Ready: Supports spray coating, electroplating, printing, etc.

Limitations: Feels light, less premium; prone to surface scratches.

Best Use: Toners, sprays, cleansers; budget-friendly product lines.

PETG

Visual Appearance: Crystal clear, thick walls, glossy like glass.

Touch & Weight: Heavier and more solid; feels high-end.

Key Advantages: Eco-friendly, printable, premium look.

Ideal For: Serums, ampoules, anti-aging skincare.

Limitations: Higher material cost, more complex processing.

AS

Visual Appearance: High gloss and good transparency.

Touch & Weight: Medium weight; clear but feels brittle.

Key Advantages: Easy to mold, visually appealing for displays.

Ideal For: Outer shells, gift box caps, double-layer packaging.

Limitations: Fragile, not impact-resistant, prone to cracking.

PP

Visual Appearance: Matte finish with a soft, natural look.

Touch & Weight: Lightweight, flexible, not transparent.

Key Advantages: Recyclable, impact-resistant, affordable.

Ideal For: Cream jars, shampoo bottles, flip-top caps.

Limitations: Not suitable for clear display packaging.

PE

Visual Appearance: Opaque with a soft, squeezable body.

Touch & Weight: Flexible, smooth, and easy to handle.

Key Advantages: Safe, durable, and great for molding tubes.

Ideal For: Sunscreen tubes, BB cream, travel-size packaging.

Limitations: Not suitable for transparent or rigid packaging.

Acrylic

Visual Appearance: Glossy and crystal-clear, glass-like finish.

Touch & Weight: Heavy, solid feel with strong visual impact.

Key Advantages: Premium look, high rigidity, good light diffusion.

Ideal For: Cream jars, foundation bottles, display packaging.

Limitations: Easily scratched, not eco-friendly.

Glass

Visual Appearance: Naturally clear with a soft, premium shine.

Touch & Weight: Heavy and solid; conveys luxury and quality.

Key Advantages: Chemically stable, ideal for active ingredients.

Ideal For: Serums, ampoules, essential oils, luxury creams.

Limitations: High cost, fragile, requires careful shipping.

Aluminum

Visual Appearance: Matte metallic finish with a sleek look.

Touch & Weight: Lightweight yet firm; cool to the touch.

Key Advantages: Light-blocking, anti-oxidation, recyclable.

Ideal For: Sunscreen, perfume, balms, premium skincare.

Limitations: Limited shaping flexibility; may dent easily.

Bamboo / Molded Pulp

Visual Appearance: Natural, earthy texture with an organic look.

Touch & Weight: Lightweight, slightly coarse, eco-friendly feel.

Key Advantages: Biodegradable, sustainable, visually unique.

Ideal For: Outer caps, gift boxes, eco-friendly packaging sets.

Limitations: Sensitive to moisture, limited in structural strength.

The choice of material can make a big difference in cost

The true impact on cost isn’t just about material type — it’s about the material’s grade, gram weight, purity level, and processing settings.

Let’s look at a real comparison:

| Item | Basic PP Bottle | Our PP Bottle |

|---|---|---|

| Material | Recycled PP | 100% Virgin PP (Food-grade) |

| Weight | 42g | 55g |

| Wall Thickness | Thin, uneven | Solid, consistent |

| Surface | Dull, grainy | Smooth, glossy |

| Defect Rate | ~15% (easy to scratch or shrink) | Less than 3%, sampling inspection |

💡 More weight doesn’t just mean “heavier”

Clients often ask, “How many grams is this bottle?”

But weight is not just about how heavy it feels — it reflects material density, structural support, and processing quality.

Lower weight bottles:

Cheaper, but easy to dent or deform

Can feel “hollow” or “flimsy”

Higher weight bottles:

More durable and stable

Feels solid and high-end

⚙️ Production settings also affect quality

Even using the same raw material, the machine settings will impact the finish.

Faster production → higher output → lower cost

But causes more defects: uneven walls, flow lines, shrinkage

Slower, optimized speed → better consistency → higher cost

But delivers better clarity, surface, and structural strength

🧠 Why does high-quality material + processing matter?

Durability: High-grade materials perform better in drop tests and long-term use

Formula compatibility: Active ingredients like oils or acids require materials that won’t react or leak

Perceived value: Customers judge quality the moment they hold your product — glossy, firm packaging builds trust

✅How to reduce cost without sacrificing quality?

Use virgin material but reduce weight slightly (e.g. 60g → 55g): saves 5–8% without major visual impact

Optimize wall thickness: Keep structure strong while trimming low-impact areas

Don’t focus only on “heavier” — the goal is smart structure, not just more material

You’re not just buying “PP” — you’re buying performance

| Material Grade | Cost | Quality | Best for |

|---|---|---|---|

| Recycled / Mixed PP |  Lowest Lowest | May deform, dull finish | Promotional / low-cost products |

| Standard PP |  Medium Medium | Acceptable finish | Mass-market skincare, personal care |

| Virgin PP (food-grade) |  High High | Clean, bright, strong | Premium skincare, export products |

Material cost ≠ Just the material name.

It depends on:

Is it virgin resin or recycled?

Is the gram weight sufficient?

Are the walls thick and solid?

Was the production machine tuned correctly?

Same premium look, but with cost optimized by half.

First ask:

“Is it virgin material?”

“What’s the gram weight and wall thickness?”

Because what you’re really comparing —

isn’t the price, but your quality strategy.

How to choose surface finish?

Beginners look at appearance — professionals look at the process. Spray coating, electroplating, hot stamping, pearlescent effects — they can all look “nice” in the end, but the cost, MOQ, and lead time are totally different.

| Process | Cost Level | Visual Effect | Durability | Typical Use | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Spray Coating |  Low Low | Matte or glossy; wide color range | Medium | E-commerce bestsellers, daily care lines | Low cost, rich colors, fast lead time | Lacks metallic feel, prone to scratches |

| Silk Screen Printing |  Low Low | Solid, sharp text or graphics | Very High | Logos, ingredient labels, volume info | Affordable, crisp lines, fits many bottle types | Limited to 1–2 colors per run; not for complex art |

| Hot Stamping |  +10%~20% +10%~20% | Partial metallic shine (logos/patterns) | High | Brand highlights, mid-range skincare | Precise, high gloss, strong branding feel | Only for flat areas, cannot cover full bottle |

| Frosting |  Medium Medium | Matte, foggy finish with soft texture | High | Minimalist skincare, high-end look | Smooth feel, fingerprint-resistant, soft visuals | Hides inner liquid details, lowers gloss level |

| Electroplating |  +30%~60% +30%~60% | Mirror-like metallic finish | Medium–High | Premium serums, gift sets, luxury lines | Luxurious look, enhances brand image | High cost, large MOQ, long lead time |

| Heat Transfer Printing |  Medium Medium | Full-color prints, gradient effects | High | Custom designs, gradient bottles, limited editions | Vibrant colors, high detail | Higher cost than silk screen; visible film seams |

| UV Printing |  Medium Medium | Glossy highlights, embossing, reflective accents | High | Logo accents, visual highlights | Enhances texture, adds contrast | Only works on flat or slightly curved surfaces |

| Pearlescent / Gradient Spray |  +50%~100% +50%~100% | Layered shine, rich visual depth | Stable | Holiday editions, promos, display pieces | Eye-catching, high design appeal | Prone to color variation, complex process, high cost |

| 3D Printing |  High High | Raised textures, strong depth effect | Stable | Custom limited editions, creative displays | Highly unique, tactile experience | Expensive, low output, not for mass production |

Spray Coating

Versatile and widely used. Offers matte or glossy finishes in various colors. Low cost and fast production, ideal for mass-market products. Downside: limited depth and metallic feel; surface may scratch easily.

Silk Screen Printing

Used for logos, text, volume markers. Delivers sharp, durable results. Low cost and compatible with most packaging materials. Downside: limited to 1–2 colors per pass; not suitable for complex images.

Hot Stamping

Applies metallic foil (gold, silver, etc.) to specific areas like logos or graphics. Mid-level cost with strong visual appeal, often used in premium packaging. Downside: only suitable for flat areas; cannot cover the whole bottle.

Frosted Finish

Creates a matte, blurred surface with a soft-touch feel. Elegant look, fingerprint-resistant, ideal for minimal or eco-conscious brands. Downside: reduces color brightness and internal visibility slightly.

Electroplating

Gives a full-body metallic mirror finish (e.g., gold, silver, rose gold). Popular for serums, gift sets, or luxury lines to elevate brand perception. Downside: higher cost, larger MOQ, longer lead time.

Hot Printing

Suitable for complex or full-color graphics, including gradients. Delivers high-resolution, photo-quality images. Downside: higher cost than silk screen; edge lines may be visible.

UV Printing

Adds glossy, reflective, or embossed effect to selected areas. Great for highlighting logos or design elements on matte or frosted surfaces. Downside: only works well on flat or mildly curved areas.

Pearl / Gradient Coating

Visually striking, with layered color transitions or iridescent effects. Perfect for limited editions or promotional packaging. Downside: high cost, requires strict quality control, color variance risk.

3D Printing

Enables custom raised textures or multi-layered effects on the surface. Highly unique and tactile, ideal for concept packaging or special editions. Downside: expensive, slow production, not suitable for mass manufacturing.

Labeling

Applying printed labels to the bottle surface — one of the most flexible and cost-effective decoration methods. Widely used on plastic, glass, or aluminum bottles, especially for small-batch or frequently updated product lines.

Why Do Bottles That “Look the Same” Cost So Differently?

Because color ≠ spray coating ≠ electroplating ≠ hot stamping ≠ silk screen printing.

Visual Effect vs Actual Process vs Cost Impact

| Visual Effect | Actual Process | Cost Impact |

|---|---|---|

| Matte grey bottle | Spray coating + drying line | Medium-High |

| Mirror-like silver finish | Vacuum electroplating + UV topcoat | High |

| Gold embossed logo | Hot stamping + precision-positioning mold | Medium |

| Gradient pearl effect | Multi-layer spray + multiple dryings + manual adjustment | High |

| Simple brand text | One-color silk screen print | Low |

Common Misunderstanding:

Common Misunderstanding:

Clients often say:

“I just want a silver bottle with a gold logo. You help control the cost.”

But what many don’t realize is:

“Silver” comes in different forms:

Spray silver — low cost, poor opacity

Electroplated silver — highly reflective, 2–3x the cost of spray

Mirror silver — requires vacuum plating and multi-step processing

And “gold logo” can be:

Gold silk print — flat appearance

Hot stamping — strong 3D effect, requires accurate mold registration

Spray-coated gold block — very difficult, not recommended

Have a limited budget? Here’s how I would help you match it —

Use existing standard mold structures + unified color scheme or spray coating; it still looks premium, but saves a big portion of the cost.

For example:

Use a universal pump + electroplated spray finish to create a high-end look

Keep the multi-part structure, but choose same-color components to unify the brand style

Remove unnecessary gaskets and replace with structural sealing — controls cost while preventing leaks

We understand you want to save money, and we also understand you want a branded look — this is exactly how we deliver “have it all” solutions.

Want to know which structure is the most cost-effective for your product?

We can suggest 3 structure options for different budgets — free of charge, with a quick 10-minute response. Let’s talk anytime.

| Variable | Cost Impact |

|---|---|

| Does the process involve multiple steps? | Each additional step (e.g. spray + hot stamping + electroplating) increases cost proportionally. |

| Does it require manual color tuning or adjustment? | Gradients and pearl finishes usually require manual handling, which leads to higher labor and material loss. |

| Is precision mold alignment needed? | Hot stamping, multi-pass printing, heat transfer, etc. require high-precision positioning tools. |

| Can the production line handle all steps in one go? | If a single line handles multiple processes → lower cost. If split across lines → higher cost due to transport and idle time. |

I suggest you ask yourself three simple questions first:

① Want full-bottle metallic shine? → Go for electroplating if budget allows; otherwise, silver spray coating is a great alternative.

② Want to highlight your brand? → Hot stamping (gold/silver) does the job with controlled cost.

③ Want a “wow” effect? → Pearl or gradient coating is super eye-catching, but comes with higher MOQs.

They may look equally shiny, but the cost varies a lot.

The more complex the structure, the higher the cost.

Sometimes, what looks like a small, simple part actually requires upgrades in the entire structure, mold, and assembly process behind the scenes.

Clients often ask —

“It’s just an extra gasket or a different pump, so why did the packaging price go up so much?”

But what clients don’t realize is the truth behind it —

✅ More complex components = higher cost

It’s not just about “adding one more piece” — it’s about replacing a simple part with a more advanced structure.

For example:

A basic pump may use a one-piece spring and valve setup, which is simple to manufacture and assemble.

When upgraded for better leak prevention or precise flow control, it might require:

Multiple independent moving parts

Tighter assembly tolerances

Additional materials (e.g., silicone seals, precision-fit sleeves)

These upgrades lead to:

More precise mold tooling

Longer assembly time

Stricter quality control requirements

All of these factors significantly increase production costs.

✅ Single-wall vs. Double-wall bottles

The appearance may look similar, but the internal structure is fundamentally different.

Double-wall bottles require:

Separate injection of inner bottle and outer shell

Precise nesting or bonding

Mold cost, material usage, and production process are all doubled

Higher assembly precision — even slight misalignment may cause leakage or looseness

✅ Integrated pump design

Looks sleek and feels premium, but requires custom molds and stricter quality standards.

Costs are typically 20%+ higher than standard pumps.

Structures are more complex, with more components (e.g., leak-proof valves, multiple springs, precision sleeves).

High molding difficulty and strict assembly precision required — otherwise, spray heads may become misaligned or have inconsistent rebound force.

A European beauty brand wanted to develop a refillable inner-bottle structure for their serum packaging. Visually, it just looked like “a bottom piece that can be pulled off.”

The client assumed it was a slight structural change

In reality, it involved:

Precise fit between inner bottle and outer bottle + leak-proof control system

Custom angle for special beveled base

Sealing structure with 4 internal components

New mold development + independent function testing

At first, the client thought it was “unbelievable,” but once we deconstructed the design and showed every part involved, they instantly understood the value behind it.

In summary:

Complex structures = cost multipliers.

Have a limited budget? Here’s how I would help you match it —

Use existing standard mold structures + unified color scheme or spray coating; it still looks premium, but saves a big portion of the cost.

For example:

Use a universal pump + electroplated spray finish to create a high-end look

Keep the multi-part structure, but choose same-color components to unify the brand style

Remove unnecessary gaskets and replace with structural sealing — controls cost while preventing leaks

We understand you want to save money, and we also understand you want a branded look — this is exactly how we deliver “have it all” solutions.

Want to know which structure is the most cost-effective for your product?

We can suggest 3 structure options for different budgets — free of charge, with a quick 10-minute response. Let’s talk anytime.

Refillable packaging ≠ cheap (Eco-friendly ≠ low-cost)

"Isn’t eco-friendly supposed to save resources? Why is refillable packaging more expensive instead?"

"Isn’t eco-friendly supposed to save resources? Why is refillable packaging more expensive instead?"

When clients hear “refillable,” their first thought is: reusable, less waste, should be cheaper.

But in reality, it’s actually a more complex packaging system — and the cost stacks up:

But we must be clear:

But we must be clear:

True eco-packaging means: reusable, disassemblable, replaceable, decomposable, and recyclable.

Each of these five things requires structural, process, and quality upgrades.

🧠 Why is eco-friendly structure actually more expensive?

Three main reasons behind it:

① Multi-structure layering (not one-step molding)

Take the common refillable packaging as an example

On the surface it looks like a single bottle, but the internal structure is actually a three-piece set:

Outer shell (responsible for brand texture)

Removable inner container (used to hold the product)

Sealing buckle + rotation mechanism (for leak prevention and easy replacement)

The inner container and outer shell must be highly matched — no looseness, but also not too tight.

Usually, public molds cannot be used → can only go through private mold development, which means high upfront investment.

② Material limitations lead to cost increase

Eco-friendly packaging often requires the use of the following materials:

PCR (Post-Consumer Recycled): recycled material from post-consumer waste

Bio-based plastics (such as PLA)

Glass / metal (reusable)

Recyclable wood, bamboo (used for caps)

These materials:

Cost 20%–80% more than conventional PP/PE

Require dedicated injection lines or mold adjustments

Are prone to deformation, have low flowability, and are harder to process

③ More difficult quality control, higher defect rate

Eco-friendly structures involve more components and more complex designs, leading to the following challenges:

QC difficulty increases: more structural fit points require strict testing and control

Higher defect rate: misaligned buckles, poor sealing, or refill failures → can lead to full-batch rework

Additional pre-shipment testing: function tests, refill trials, leak tests are required

Solution: Eco-friendly ≠ expensive — there are many “balanced approaches.”

Being sustainable is great, but that doesn’t mean you have to start with the most expensive refillable structure.

Here are some smarter options we can help you with:

These solutions help you stay true to your brand values while making your budget work smarter.

We recommend considering all three aspects — materials, structure, and user guidance — to find a sustainable solution that’s practical and achievable.

We’ll evaluate your packaging structure and recommend budget-friendly solutions.

Click the WhatsApp icon or fill out the form in the bottom right — we’ll get back to you right away

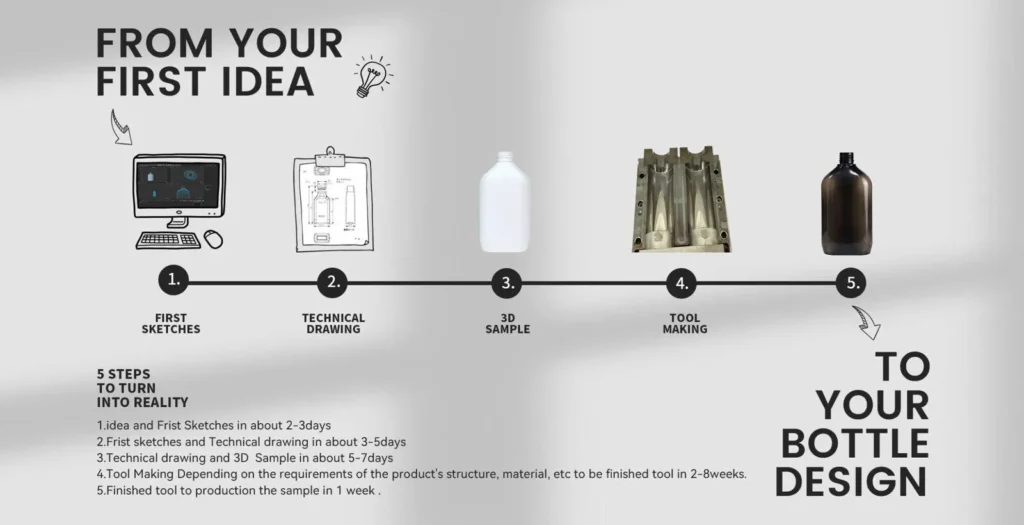

Mold fee ≠ a “scam charge”

“I only changed the bottle neck shape — why are you saying it needs a new mold and costs thousands?”

To many clients, mold fees seem like “hidden charges” or “unjustified costs” — but in reality, they’re one of the most misunderstood yet essential parts of custom packaging.

A mold isn’t like clay that can be reshaped at will — it’s a high-precision industrial system. Once made, it cannot be casually modified without affecting the structure, fit, or function.

A mold is a high-precision metal tool used to manufacture packaging components such as bottles, caps, or pumps. It shapes raw materials into specific forms through processes like injection molding, blow molding, or die casting.

This is not 3D printing — and definitely not something you can tweak on the fly.

Even a small structural change may require a complete adjustment of the entire production system.

What many clients consider a “small change”

· Widening the bottle neck by 2mm

· Flattening the bottom

· Slightly shallower threads

· Softening the shoulder curve

But from an engineer’s point of view, these actually affect

· Does the injection flow path need to change? (Can the original gate still be used?)

· Is the demolding direction still workable? (Will the wider neck cause mold jamming?)

· Will the shrinkage rate go off? (Different shapes affect cooling flow speed)

· Will the structure still match the existing pump or cap?

→ new mold cores

→ new mold base

→ revised parting surfaces

It’s not just “polishing a bit” — it’s re-engineering the mold.

Here’s the simple breakdown

→ A standard mold structure shared by multiple clients. No mold fee is required, but the structure cannot be modified.

→ A fully custom structure developed exclusively for your brand, including unique bottle shape, size, and thread details. One-time investment, but reusable for future orders.

| Item | Public Mold | Private Mold |

|---|---|---|

| Mold Fee | None | One-time development cost |

| Custom Freedom | Structure fixed | Fully customizable |

| Exclusivity | Shared among brands | Exclusive to your brand |

| Best for | Fast launch / Cost control | Long-term / Brand differentiation |

· Material type: Glass vs. plastic molds have very different requirements for steel grade and precision

· Structural complexity: Single-wall bottles are simpler, while vacuum bottles require higher mold accuracy

· Product size: Larger formats need more material and are harder to shape — increasing tooling cost

· End use: Some clients need only a sample mold for presentation, others require mass production — the mold design and investment strategy differ

How Is Mold Cost Actually Calculated?

How Is Mold Cost Actually Calculated?

It’s not about “random quotes,” but a very clear industrial costing logic:

| Cost Factor | Cost Impact |

|---|---|

| Material Type (PP / PET / Acrylic / PETG) | Determines the mold’s required steel type and durability |

| Product Size (30ml / 100ml / 500ml) | Determines the mold cavity volume and tonnage required for molding |

| Structural Complexity (single wall / double wall / snap-on / inner cup) | Determines number of mold cavities, part fit requirements, and demolding complexity |

| Surface Finish Requirements (glossy / matte / frosted) | Determines precision level and surface processing difficulty |

| Number of Cavities (2-cavity / 4-cavity / 8-cavity / 16-cavity) | Balances production efficiency vs. upfront investment |

| Tool Life (a few thousand? or hundreds of thousands?) | Determines whether to use soft tooling for prototyping or hard tooling for mass production |

We typically recommend three mold strategies based on your current brand stage:

| Situation | Recommended Mold Strategy | Reason |

|---|---|---|

| Just getting started / small batch test | Use public mold structure, differentiate via color, coating, or printing | Lower cost, faster turnaround |

| Clear production plan / strong positioning | Develop brand-exclusive private mold | Builds unique brand visuals and boosts trust |

| Seeking light customization / cost-sensitive | Suggest joint mold development or mold sharing | Share development cost with similar clients—save money and avoid duplicates |

We can help you evaluate it with zero guesswork:

Production Equipment Capability

The same process, done on different machines, can lead to completely different results — in appearance, efficiency, yield rate, and even feasibility

Not All Machines Are Created Equal

Not All Machines Are Created Equal

Think of it this way:

They’re all “cameras,” but some are just good for passport photos, while others shoot high-end fashion campaigns.

| Process | Equipment Difference | Cost Impact | Common Misconception |

|---|---|---|---|

| Silk Screen Printing | Basic single-color machine vs. high-speed servo multi-color press | Single-color machines print one at a time; servo machines print 4 colors in one go | “It’s just a logo — what’s the difference?” |

| Spray Coating | Manual spray + fixed temp vs. automatic line + multi-zone drying | Manual = color inconsistency & low efficiency; auto line = stable but higher setup cost | “Spray painting is just adding color, right?” |

| Hot Stamping | Manual alignment vs. CCD auto-alignment | Manual = misaligned logos; CCD = clean, accurate stamping | “A little off-center is fine, no big deal.” |

| Assembly | Semi-auto vs. fully automatic line with in-line inspection | Auto line integrates spring/washer assembly, inspection & sealing | “Isn’t manual assembly cheaper?” |

These invisible factors are what actually drive the cost behind your packaging.

Why You Should Care About Equipment Differences

Why You Should Care About Equipment Differences

Because it directly affects:

-

Lead time: Old machines take 2 days for 5,000 pcs; new machines do it in half a day.

-

Visual consistency: Is the logo off-center? Is the print fading? Are the lines blurry?

-

Batch consistency: Will your 5,000 or 10,000 sets look exactly the same?

A U.S. client needed 3-color printing + gold foil logo.

Factory A used a single-color press and printed 3 rounds, then hot-stamped.

-

Result: Misaligned logo, blurry layers, 3–4mm print offset, high rework rate.

We used a 4-color servo press + CCD hot stamping:

-

One-pass printing, perfect alignment

-

Crisp print and flawless foil edges

-

98.7% yield rate, zero complaints

How to Tell If a Supplier’s Equipment Matches Your Brand Needs?

How to Tell If a Supplier’s Equipment Matches Your Brand Needs?

Not necessarily.

Advanced equipment means:

-

Higher efficiency → Lower unit cost at scale

-

Better precision → Fewer defects, less waste

-

Process integration → Print + spray + stamp in one go

How can you assess whether a supplier’s equipment meets your brand’s requirements?

How can you assess whether a supplier’s equipment meets your brand’s requirements?

Here are a few key questions you can ask us:

① What type of silk screen printing machine do you use? Is it multi-color linked? Does it support auto-alignment?

② Is your spray coating line manual or fully automated? Do you use multi-zone temperature control?

③ Do you have in-line visual inspection systems installed?

④ Can you complete spraying + printing + hot stamping in a single integrated process?